Auckland Anodising

Anodising in the Auckland region

Advanced Anodising Ltd has been providing its anodising services to customers in the Auckland region for over 5 years. Here are 7 reasons why our customers in Auckland locations choose to use Advanced Anodising Ltd -

- Fast turn around: We aim to have all anodising jobs completed in 5 working days or less

- Full range of anodised colours: Why not have a look at our 'colour' page and see for yourself

- Easy freight: Freight to Advanced Anodising in Tokoroa is easy with all major courier firms knowing exactly where we are and is very reasonably priced. We will organise the return freight so you dont have to. Freight is typically only a small portion of the cost of any machining job and in addition to our fast turn around you cant lose.

- Full anodising service: We offer standard, marine and hard anodising. Check out our 'services'.

- Free samples: Not sure if anodising is right for your product? Sent us a sample piece and we will anodise this for FREE

- Knowledgable staff: We are allways happy to offer advice on your anodsing needs and if we cant help you we are happy to direct you to someone who can. That is why we have made our website as informative as possible. One of our most popular pages is 'choosing the right alloy for your anodising'

- Guaranteed completion: If we agree on a completion date and we dont deliver then you receive 50% of the cost of the anodising

Call us now on 0800 44 55 95 or fire us an email - This email address is being protected from spambots. You need JavaScript enabled to view it. to enquire about our services

Check out the rest of our site to see how we can help you

Tauranga Anodising

Tauranga Anodising

Advanced Anodising Ltd has been providing its anodising in Tauranga for over 5 years. Here are 7 reasons why our customers in Tauranga and other Bay of Plenty locations choose to use Advanced Anodising Ltd -

- Fast turn around: We aim to have all anodising jobs completed in 5 working days or less

- Full range of anodised colours: Why not have a look at our 'colour' page and see for yourself

- Easy freight: Freight to Advanced Anodising in Tokoroa is easy with all major courier firms knowing exactly where we are and is very reasonably priced. We will organise the return freight so you dont have to.

- Full anodising service: We offer standard, marine and hard anodising. Check out our 'services'.

- Free samples: Not sure if anodising is right for your product? Sent us a sample piece and we will anodise this for FREE

- Knowledgable staff: We are allways happy to offer advice on your anodsing needs and if we cant help you we are happy to direct you to someone who can. That is why we have made our website as informative as possible. One of our most popular pages is 'choosing the right alloy for your anodising'

- Guaranteed completion: If we agree on a completion date and we dont deliver then you receive 50% of the cost of the anodising

Call us now on 0800 44 55 95 or fire us an email - This email address is being protected from spambots. You need JavaScript enabled to view it. to enquire about our services

Check out the rest of our site to see how we can help you

Anodising Aluminium - Choose The Right Aluminium Alloy for your Anodising

Choosing the right Aluminium alloy for an anodizing job can be a difficult process. There are many types of Aluminium alloy available and most come in various tempers. Alloys are divided into groups each with certain physical characteristics and properties that may or may no suit your needs. In addition each of these alloys will anodise differently and this will need to be taken into account when selecting your Aluminium alloy.

If you are intending on making a product out of Aluminium that you intend to anodise, then in addition to the physical characteristics of the Alloy it is important that consderation is taken of the following;

- Is the main purpose of the anodising protective, decorative or both?

- Do you require a matt or bright finish?

- Do you require a natural or coloured finish?

- Do you require hard anodising?

The answers to these question should help you determine the most suitable alloy to use.

Aluminium alloys can be divided into 2 broad groups - Wrought and Cast Alloys

Wrought Aluminium Alloys

Wrought alloys are further divided into 8 groupings called series. Each series has one or more alloying metals mixed with the Aluminium but always one or two main ones. For example the 6063 is part of the 6000 series and so the main alloying constituents are Magnesium and Silicon, but can also contain very low quantities of Iron, Copper, etc. The alloy mix will determine the natural corrosion resistance, extrudability, tensile strength, heat treatability, anodising ability, etc...

With regards to corrosion resistance, the purer the Aluminium the better the natural corrosion resistance of the metal. Copper has the most detrimental affect on corrosion resistance and Magnesium the least. That's why 2000 series alloys with Copper as the main alloying constituent performs poorly and the 5000 series of alloy with Magnesium as the alloying constituent has the best corrosion resistance, with the exception of pure Aluminium.

1000 Series Aluminium Alloy (Pure)

This series of Aluminium alloys is considered to be 'pure' with purity no less than 99%. This series of alloys is primarily used for electical conductivity or food purposes. While these alloys can be hardened they are not typically used where hardness is a requirement. They all anodise well but are not suited to machining unless they have been hardened.

| Alloy | Machining |

Protective Anodising |

Colour Anodising |

Bright Anodising |

Hard Anodising |

Uses |

| 1050 | Fair (H8 - Good) | Excelent | Excelent | Very Good | Excelent | |

| 1080 | Poor (H8 - Good) | Excelent | Excellent |

Very Good - Excellent |

Excellent | |

| 1200 | Fair (H8 - Good) | Very Good | Very Good | Good | Excellent |

|

2000 Series Aluminium Alloy (Copper)

This series is alloyed primarily with Copper to give the alloys in this series a high strength and very good machining characteristics. These alloys are sometimes referred to as 'free machining', although this does not always refer to the 2000 series. Sometimes 6061 is also called 'free machining' as it the best machining alloy out of the 6000 series of Aluminium alloys. These alloys tend to have poor corrosion resistance (certainly when exposed ot the weather) and so they are typically coated in one form or another. While these alloys can be anodised, the anodising does not perform as well for other alloys with regard to corrosion resistance. The anodising for this group of Aluminium alloys tends also to be darker than for other alloys (also more matt) and so anodising is normally only suitable for dark colours, hence these metals are completely unsuitable for a bright anodised finish. 2000 series alloys can show pitting on anodising. We recommend that if you require anodising for decorative purposes, where possible avoid using 2000 series alloys.

2024 Aluminium alloy is normally found in aircraft manufacture, where it is used for its high strength. Where it is used for external sheet/skin on an airframe it is most often in the form of 2024 coated in 'pure' aluminum. This gives the part better corrosion resistance than the main alloy.

| Alloy | Machining |

Protective Anodising |

Colour Anodising |

Bright Anodising |

Hard Anodising |

Uses |

| 2011 | Excellent | Fair | Fair (Dark only) | Unsuitable | Good* | Machined parts |

| 2014 |

Good (T6 - Very Good) |

Fair | Fair (Dark only) | Unsuitable | Good* | Truck bodies |

| 2024 | Very Good | Fair | Fair (Dark only) | Unsuitable | Good* |

Aircraft frames and parts |

* - One thing to be aware of with hard anodising high copper alloys is the risk of 'burning'. Hard anodising of these alloys would be entirely at the owners risk.

3000 Series Aluminium Alloy (Manganese)

This series is alloyed primarily with Manganese that results in the Aluminium alloys in this series having excellent corrosion resistance that makes them suitable for architectural/outdoor applications as well in areas where foods or other corrosive chemicals are used. These Aluminium alloys also have excellent welding characteristics. 3000 series alloys can be found in a wide range of applications from drink cans to roofing to heat exchangers. The anodised coating offer good protection over what is already a corrosion resistant metal. One thing to keep in mind is that the level of Manganese present with result in the natural anodised coating varying from a light grey all the way to a brown. This can limit light colours but is not usually a major issue. It can be an issue if you have several sheets/items of the same 3000 series alloy that you require to be natural anodised as there is a good chance there will be a variation in the degree of grey/brown that shows in the anodised coating. Also, the level of Manganese makes these alloys a poor choice for those that require bright anodising.

| Alloy | Machining |

Protective Anodising |

Colour Anodising |

Bright Anodising |

Hard Anodising |

Uses |

| 3103 | Fair (H8 - Good) | Good | Good | Poor - Fair* | Good |

* - Depends on the level of alloying Manganese present. The lower the level of Manganese the brighter the potential results.

4000 Series Aluminium Alloy (Silicon)

This series is alloyed primarily with Silicon which gives these alloy very good flow characteristics when molten. There are two variants that are most commonly used in this series, 4032 and 4043. 4042 is primarily used in forging processes where the high silicon content alloys the alloy to flow easily into even very complex dies. The alloy can be heat treated and offers good overall strength. 4043 is used as welding wire and similarly to 4032 the high silicon content gives excellent flow-ability in a molten state to ensure the weld join is fully filled.

4000 series alloys have good corrosion resistance and anodise well. They are not, however suited for any decorative anodised finish. The natural anodised coating tends to be a very dark grey to black in colour. Hence they are completely unsuitable for both coloured and bright finishes. Our advise is that if you require welding prior to anodising that you use 5356 welding wire and NOT 4043. Unless of course the look of the product is not important.

5000 Series Aluminium Alloy (Magnesium)

This series is alloyed primarily with Magnesium which results in a variety of very useful features. They are strain harden-able and have a moderately strength which relates directly to the Magnesium content. The higher the Magnesium content the higher base strength. Corrosion resistance is very high, even in salt water applications making it useful for a wide range of applications. These alloys also retain a high degree of strength at very low temperatures and by very low we mean as low as -270 degrees Celsius. Lastly is that they a very suitable group of alloys for welding with a wide variety of techniques. This is shown by the fact that 5356 is used as welding wire. 5356 anodises well and colours well.

The 5000 series of Aluminium alloys finds uses in a wide range of application due to its very useful features from architectural/out door applications, to bridge building, marine applications, storage vessels, automotive panels and even specialty work such as automotive bright trim.

| Alloy | Machining |

Protective Anodising |

Colour Anodising |

Bright Anodising |

Hard Anodising |

Uses |

| 5005* | Fair (H4/8 - Good) | Excellent | Excellent | Excellent | Excellent |

Small boats Architectural etc |

| 5083 | Good - Very Good | Very Good | Very Good | Good | Excellent |

Marine Automotive Building, etc |

| 5251 | Good - Very Good | Very Good | Very Good |

Good - Very Good |

Excellent |

Marine Automotive Building, etc |

* - For 5005 it is recommended that for the best anodising results that the Silicon level is <0.1% and that the Magnesium level between 0.7% and 0.9%. While we understand that the buyer of the Aluminium alloy can not know what the exact makeup is of the batch of alloy they are buying, they need to be aware that slight variations in the alloy mix can result in a variation of the anodising outcome.

6000 Series Aluminium Alloy (Magnesium & Silicon)

This series is alloyed primarily with Magnesium and Silicon. They have a moderately strength but are heat treatable. They have good corrosion resistance although not quite that offered by the 5000 series. One characteristic that makes this series very useful is its ability to be easily extruded into a wide variety of shapes and lengths. Two common varients of the 6000 series of Aluminium alloy are 6061 and 6063. The 6061 offers greater strength and machinability that 6063 but the latter has better extrudability. The 6000 series of Aluminium alloys have found wide use in the building industry from window frames to bridges because of their extrudability, corrosion resistance and tensile strength. In addition these alloys are readily welded and all tend to anodise well. 6063 anodises better than 6061 particularly where bright applications are required.

| Alloy | Machining |

Protective Anodising |

Colour Anodising |

Bright Anodising |

Hard Anodising |

Uses |

| 6061 |

T4 - Good T6 - Very Good |

Good | Good | Fair* | Very Good | |

| 6063 | Good | Very Good | Very Good |

Good - Very Good* |

Excellent |

* - With these alloys the primary factor that indicates the brightness in bright anodising is the Iron content. Once the Iron content >0.2% the coating will tend towards a matt finish. For a true bright finish it is recommended the Iron content is <0.1%. 6061 has a maximum allowable Iron content of 0.7% (No minimum), while 6063 has a maximum Iron content of 0.35% (No minimum). That why tyically 6063 bright anodises better than 6061 but also that it possible to get a wide variation in bright anodising results as the amount of Iron could vary quite a bit from batch to batch. It is possible that one batch of 6061 bright anodises better than one batch of 6063. The trouble is unless your Aluminium supplier can tell you before hand the exact composition, the final result will not be known until after anodising.

7000 Series Aluminium Alloy (Zinc)

This series is alloyed primarily with Zinc. The primary feature of this series of Aluminium alloys is the high strength and in particular the very high tensile strength. Not as corrosion resistant as the 5000 and 6000 series of alloys, they are typically coated one way or another. In aircraft applications they are normally found in the Alclad form, that is they have been coated in 'pure' Aluminium. The table below shows 2 examples of the 7000 series, they are not the best alloys for anodising compared to other. However we have found that motorbike rims such as 'Excel' anodise very well and colour well with a very bright finish if mechanically polished. Our experiences with bright dipping these has however not been good, so that is not an available option.

| Alloy | Machining |

Protective Anodising |

Colour Anodising |

Bright Anodising |

Hard Anodising |

Uses |

| 7020 | Fair (T6 - Good) | Fair | Fair | Unsuitable | Good |

Armoured vehicles Motorbikes |

| 7075 | Very Good | Fair | Fair | Unsuitable | Fair | Aircraft |

Cast Aluminium Alloys

Cast alloys tend to be more of a mixed bag when it comes to anodising. It really comes down to whether you are intending on only anodising for corrosion resistance, decoration or brightness. Silicon is a common alloying ingredient to most castings and this affects the way the cast alloy will anodise. The following is based on UK designations for cast alloys;

Cast Alloys Suitable for Protective Anodising

Excellent corrosion resistance - LM0, LM5, LM31

Good corrosion resistance - LM4, LM16, LM20, LM22, LM25, LM27

Fair corrosion resistance - LM2, LM6, LM9, LM12, LM13, LM21, LM24, LM26

Unsuitable for anodising - LM28, LM29, LM30

Cast Alloy Suitability for Colour Anodising

Excellent colour - LM0, LM5, LM31

Good colour -N/A

Fair colour - LM4, LM12, LM16, LM20, LM22, LM24, LM25, LM27 (Dark shades onl;y)

Unsuitable fo colour - LM2, LM6, LM9, LM13, LM21, LM26, LM28, LM29, LM30

Cast Alloy Suitability for Bright Anodising

Excellent bright results - LM0

Good bright results - LM5

Fair bright results - LM31

Unsuitable for bright - All the rest

The difficulty we normally experience with castings that we receive, is that the type of casting we are presented with is an unknown. Quite often the parts were bought either as new or second hand, so there is quite often very little to go on. The exception being custom made cast parts. It should also be noted that this list of cast alloys is by no means exhaustive, as there are further British cast alloy designations as well as a whole host of US cast alloy designations. One generalisation that can be made is that cast alloys are typically not suitable for decorative anodising.

Important Note When Buying Aluminium Alloys

Always ask about the anodising characteristics of what you are buying. Ensure that you get what you ask for with regards to the grade and temper of the alloy. Please be aware that in the manufacturing process there will be variations from batch to batch of even the same alloy and that this may result in variations in the final anodising. Each alloy type will typically have minimums and maximums for each alloying constituent. The range can have an impact, for example 6061 can have a maximum of 0.7% Iron and a minimum of 0%. Anything is this range is still in specification but only those batches that have below 0.2% Iron are suitable for bright anodising. The problem is that these variations are normally only apparent after the anodising has been done.

The tempering process does not have a marked affect on the final anodising. There are instances where it does impact on the anodised outcome. One example is shown below;

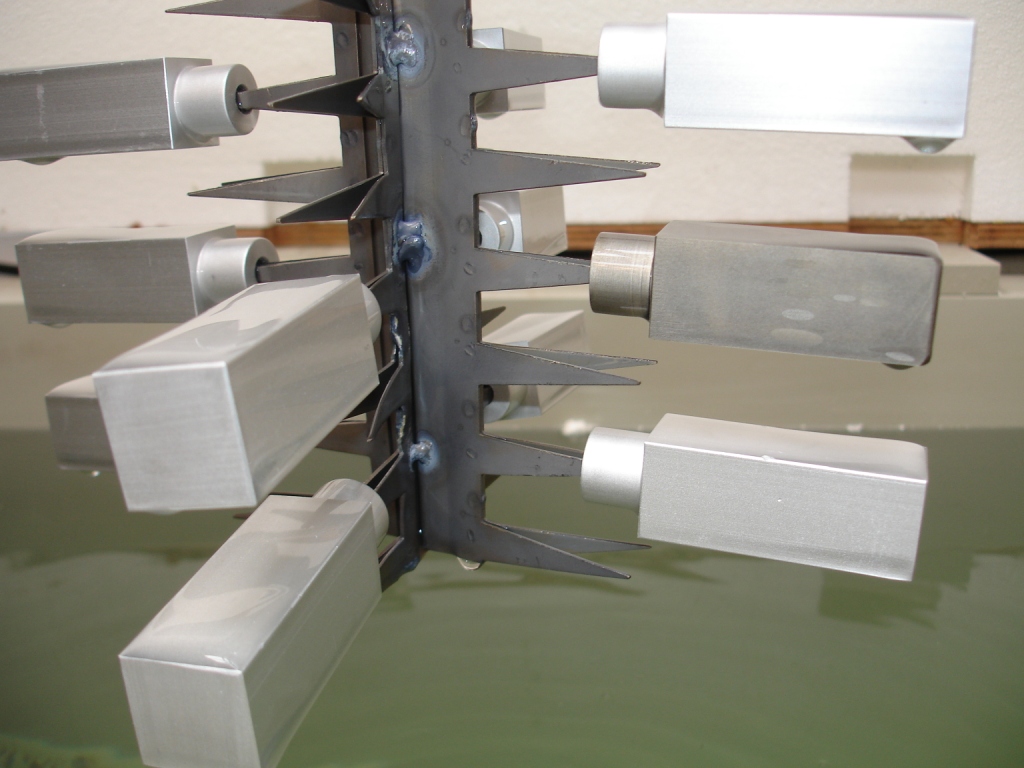

All the parts are from the same small production run but one piece was made from a different billet with a different temper with the very obvious crystal structure.

The above parts have been etched for 15 minutes and are photographed just out of the de-smut bath. As can be seen from the parts, they are all the same but for one. The customer had bought all the same alloy but one piece that had been given as a different temper. While typically this is not an issue, in this instance it can be seen that one of the components still has a dark smut but also tear drop shaped patterns on the metal itself. These tear drop shapes will still be visible in the final anodised product. The etching gives the items a nice matt finish and shows the crystal structure of the metal, certain tempers have large crystal structures and these may not be attractive. In this instance the parts are to be decoratively anodised, so it may be an issue.

The following photo shows 2 of the previously discussed parts after anodising. The bottom part has an attractive matt finish, where as the top part shows the potential negetive impact of having different alloys or tempers in the same production run and does not appear suitable for a decorative finish.

We have seen examples where a customer had bought 2024 alloy but had recieved 6061/6063. An other cusotmer had bought 6061 T5 but received a mixture of 6061 T5 and T6 for decorative anodising. In most instances the variation in what is ordered and supplied is not an issue, but as has been shown that is not always the case.

This also highlights that if the alloy is completely unkown before anodising the final outcome can not be predicted with certainty.

Hard Anodising

Hard Anodising

Hard anodising is anodising produced under very specific operating conditions that produces very functional coatings. These hard anodised coatings are typically 50 microns in thickness and have excellent wear and corrosion resistance characteristics. Hard anodising has many uses and is typically found where either a high degree of wear resistance or corrosion resistance is required i.e. sprockets, pulleys, boat parts, pistons e.t.c.

The dimensions of our hard anodising bath are - 2750mm L x 750mm W x 650mm D

Functional characteristics of hard anodising

While the typical hard anodised coating is 50 microns thick, coatings ranging from 30 - 75 microns can be readily achieved and if required a 100 microns may be possible. One important point point about the coating thickness is that a greater coating thickness may not necessarily improve the functional performance of the hard anodised coating. Coatings over 75 microns can have worse wear performance than the standard 50 micron. Also a coating of 100 microns may not perform any better with regards to corrosion resistance due to the high likely hood of the coating crack.

Interestingly enough there is no set standard for how hard, hard anodising must be. The hardness can vary quite a lot and depends on having operating condition that favours smaller pores, choice of alloy and the actual coating thickness. While the hardness of hard anodising in comparison to hard chrome and heat treated steel is certainly lower, hard anodised coatings are normally equal or better when it comes to comparing wear resistance.

What are the best alloys for hard anodising

Alloys from the 5000, 6000 and 7000 series are regarded as best for hard anodising. Those alloys that are high in Copper (>%) and/or Silicon (>%) are generally not suitable for hard anodising. Due to the high copper content found in 2000 series alloys, there is a high risk of 'burning', and operating parameters have to be very carefully controlled to try to avoid this. We require that customers sign a waiver in the event that 2000 grade alloys require hard anodising and will not attempt to get the coating over 40 microns.

Hard anodised colours

As hard anodised coatings are both very thick (50+ microns) and dense. Hard anodising in its natural state varies in colour from a dark grey to brown shades. Due to this hard anodising is not suitable for most colour dyes except black. In most cases this is not an issue as the purpose of the coating is functional and not decorative.

Considerations for hard anodising

- Size of the parts - With hard anodising you can expect to see a dimensional change of roughly 1/2 the coating thickness that is applied. E.G If anodised to 50 microns then a dimensional change can be expected to be 25 microns on every surface. This will need to be factored in prior to machining. Just as the outward size of part increases, similarly bores will shrink by the same ratio and overall by the total coating thickness, so masking may be required. Please note that this is just a general rule of thumb as there are factos that influence this such as the ammount of pre-etching, type of alloy, and complexitiy of shape of the part e.g. internal surfaces do not experiance the same amount of coating growth and dimensional change as external surfaces.

- Surface finish - If wear resistance is critical for your components, then the surface finish prior to anodising must as smooth as possible. If not there is a likely hood that any raised spots of the coating may fracture off and become trapped between the 2 sliding surfaces, resulting in a greater rate of wear than would otherwise be the case.

- Joins - Any areas that are riveted or spot welded should be avoided

- Earth point - Should an earth be required, this must be masked prior to anodising due to the high electrical resistance of the anodised coating and the difficulty in removing the coating after anodising.

- Non-Aluminium Parts - As with standard anodising, attachments such as those made from steel or other metals will be severely damaged or destroyed.

- Mixed Alloys - Avoid this where possible, where as with standard anodising where certain alloys can be anodised together this may not be the case for hard anodising. Slight differences in the make up of the alloy can result in one anodising at a much greater rate than the other. In other words, slight variations that do not rate in standard anodising are magnified in hard anodising. We will only anodise 6000 grade with other 6000 grade, etc.

- Forming - As with all anodising any bending/forming of the product needs to be done prior to the anodising process. Aluminium Oxide will crack and fracture if bent

- Sharp Edges - Anodising grows perpendicular to the surface. This means that on sharp outer edges there will be a 'void' where there is no anodising, while on sharp inside corners there will be what is termed a 'crash' where the coating grows into itself. Neither is desirable as it will lead to quality defects. There are some guidelines that can be followed to avoid these issues and these are laid out in the specification MIL-A-8625F. The following table identifies an optimum amount of curvature relative to coating thickness that will help avoid 'voids' and 'crashes'.

| Target coating thickness | Radius of curvature |

| 0.001 inch / 25 micron | 1/32 inch |

| 0.002 inch / 50 micron | 1/16 inch |

| 0.003 inch / 75 micron | 3/32 inch |

- Threads - There can be quite a dramatic change in thread dimensions during the hard anodising process. It is commonly quoted that the pitch diameter will change by a ratio of 4 to 1 to hard anodising build up. To deal with this either the threads need to be made under size or alternatively masked, if in doubt it could be worthwhile getting some samples done.

- Sealed or unsealed - This will depend on whether your primary purpose for hard anodising is wear or corrosion resistance. If wear resistance is the more important then the parts would be left unsealed as this maintains the maximum wear resistance. Unsealed anodising has the added functionality of 'holding' lubricants such as oils in the case of hard anodised pistons. In the event that corrosion resistance is the critical factor then closing the pore structure by sealing ensures maximum corrosion resistance or alternatively using a secondary coating to close over the pore structure E.G. Teflon or similar. One down side to sealing is that the wear resistance of the coating is slightly reduced. Sealing may also be required where the hard anodising has been dyed.

NB - Cracking: It is common for hard anodising to show micro cracking in the surface. Due to the fact that hard anodising takes place at about 0 degrees and the the fact that the co-efficient of expansion for Aluminium Oxide is only 20% that of Aluminium means that even taking the items from the anodising tank to the rinse tank can result in cracks forming. A very small amount of cracking does not impact on the functionality of the coating. In some instances very thick sealed coatings (100+ microns) may have more pronounced fractures that can adversely impact of the corrosion resistance of the hard anodised coating.

Use Suitable Surface Finish Prior to Anodising

Anodising does not hide any marks, so any mark present on the surface of the metal prior to anodising will show through at the end. The quality of the surface finish prior to anodising will depend on your requirements for the final look of the product.

Die lines

Die lines are a result of the manufacturing process to make extruded aluminium lenghts. The degree to which these show up in the raw product varies depending on the manufacturing conditions at the time. Caustic etching will reduce the impact of die lines but will not entirely remove them, so die lines will remain visible after the anodising process.

Machining marks

A lot of the work now being anodised are CNC machined parts. Any machining marks present prior to anodising will show through at the end, this is not always a negative as certain machining swirls and the like, give a really nice look.

Bead Blasting

Bead blasting is a great way of giving parts a uniform finish. With regards to anodising you will need to note, that to get a nice anodised finish the parts will require a longer etch time and that this may impact on any tolerances and secondly that the parts will be fairly matte in appearance.

Where possible Advanced Anodising Ltd will notify customers customers if they have concerns that the final anodised look may not be what the customer is after as a result of the surface preparation. Advanced Anodising Ltd takes no responsibility for any quality issues that relate to the preparation of the parts prior to anodising. Advanced Anodising will assume that customers are aware of the quality of the surfaces on the parts and can not be held responsible if this does not actually meet their requirements.